|

| August 25, 2015 | Volume 11 Issue 32 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Space: NASA's robotic manufacturing system will build biggest composite rocket parts ever

A titan now resides at NASA's Marshall Space Flight Center in Huntsville, AL. This titan is no Greek god, but one of the largest composites manufacturing robots created in America, and it will help NASA build the biggest, lightweight composite parts ever made for space vehicles.

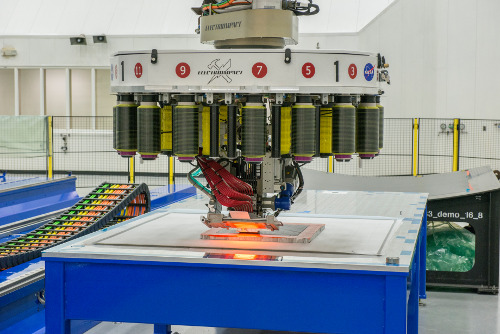

A new 21-ft new robot arm moves on a track in the Composites Technology Center in NASA's National Center for Advanced Manufacturing at Marshall Space Flight Center in Huntsville, AL. The robot head is dispensing hair-thin carbon fiber tape in precise patterns to make a large composite panel. [Credits: NASA/MSFC/Fred Deaton]

The robot is part of the ISAAC (Integrated Structural Assembly of Advanced Composites) project, which saw the installation of a similar robotic manufacturing system at NASA's Langley Research Center in Hampton, VA, at the end of 2014.

The robot's head has 16 spools of composite fiber tape that it releases in precise patterns to make both small and large objects. As the fibers are released, they are heated so that they adhere to various surfaces. The head can be changed out for different projects. [Credits: NASA/MSFC/Fred Deaton]

"Marshall has been investing in composites for a long time," says Preston Jones, deputy director of Marshall's Engineering Directorate. "This addition to Marshall's Composites Technology Center provides modern technology to develop low-cost and high-speed manufacturing processes for making large composite rocket structures. We will build and test these structures to determine if they are a good fit for space vehicles that will carry humans on exploration missions to Mars and other places."

Last year, NASA engineers tested a full-scale composite cryogenic rocket fuel tank, shown here, in a test stand at NASA's Marshall Space Flight Center in Huntsville, AL. [Credits: NASA/MSFC/David Olive]

It takes myriad different materials to build a space vehicle like NASA's new Space Launch System, a heavy-lift rocket designed to take explorers on deep space missions. The lighter the rocket, the more payload -- crew, science instruments, food, equipment, and habitats -- the rocket can carry to space. Lightweight composites have the potential to increase the amount of payload that can be carried by a rocket along with lowering its total production cost. NASA is conducting composites manufacturing technology development and demonstration projects to determine whether composites can be part of the evolved Space Launch System and other exploration spacecraft, such as landers, rovers, and habitats.

"The robot will build structures larger than 8 m (26 ft) in diameter, some of the largest composite structures ever constructed for space vehicles," says Justin Jackson, the Marshall materials engineer who installed and checked out the robot and who helped build and test one of the largest composite rocket fuel tanks ever made [see Designfax story here]. "Composite manufacturing has advanced tremendously in the last few years, and NASA is using this industrial automated fiber placement tool in new ways to advance space exploration. Marshall's investment in this robot will help mature composites manufacturing technology that may lead to more affordable space vehicles."

The robot travelled across the country from Electroimpact, Inc., in Mukitteo, WA. Electroimpact engineers worked with Marshall engineers to customize the robot and supporting software for building large space structures. The robot is mounted on a 40-ft-long track in Marshall's Composites Technology Center that is part of NASA's National Center for Advanced Manufacturing. This center already has support infrastructure necessary for composite manufacturing: large autoclaves, curing chambers, test facilities, and digital analysis systems.

The ISAAC system robot is an adaptation of a KUKA standard industrial robot. To make large composite structures, the robot travels on a track, and a head at the end of its 21-ft robot arm articulates in multiple directions. The head can hold up to 16 spools of carbon fibers that look like pieces of tape and are as thin as human hairs. The robot places the fibers onto a tooling surface in precise patterns to form different large structures of varying shapes and sizes. In what looks like an elaborate dance, the tooling surface holds the piece on a rotisserie-like system on a parallel track next to the robot. The robot head can be changed for different projects, which makes the system flexible and usable for various types of manufacturing.

In recent years, carbon fiber composite materials have proven their worth in aircraft such as the Boeing 787. Now, researchers want to improve them and expand their uses.

ISAAC gives researchers more flexibility in arranging the ribbons and the fibers they contain. Conventional composites used in existing vehicles consist of many layers of fibers oriented at 0, 45, and 90 degrees. ISAAC can lay them down along a curving path, following a pattern designed to increase strength and performance.

The first project that the robot will tackle is making large composite structures for a Technology Demonstration Mission (TDM) program managed by Marshall for the Space Technology Mission Directorate. For that project, engineers will design, build, test, and address flight certification of large composite structures similar to those that might be infused into upgrades for an evolved Space Launch System.

This closeup shows a sheet of carbon fiber-and-epoxy ribbons created by ISAAC. [Credits: NASA/David C. Bowman]

"These new robotic fiber placement tools are game changers, because they can drastically reduce the cost and improve the quality of large space structures," says John Vickers, the manager for NASA's National Center for Advanced Manufacturing and the manager for the TDM composites project. "The automated digital capability aids in the design and development process and makes it more precise and efficient. This helps NASA meet the high reliability standards required to develop a process for building space vehicles that transport humans on deep space missions."

The large structures built by the robot will be tested in nearby Marshall structural test stands where spaceflight conditions can be simulated.

"Both systems [at Langley and Marshall] will work on multiple projects at the same time," says Kimberly Newton, NASA Public Affairs, Marshall Space Flight Center. "Marshall is investigating whether there is an advantage to building large composite structures for the Space Launch System and other spacecraft. ... Having two separate robotic systems allows Langley to focus efforts on research at low technology readiness levels where a great deal of advancement is needed before the technology can be infused and used in flight vehicles. Marshall will focus on a high technology readiness level, where technology is actually used to build structures that can be tested in Marshall's test stands. Marshall has facilities that allow large structures to be made, characterized, and tested. Understanding the manufacturing process will give NASA the confidence to develop repeatable manufacturing process that can be shared with industry to make flight hardware."

Source: NASA [This article was compiled from reports by NASA editors Lee Mohon (Marshall) and Sam McDonald (Langley), and answers to some Designfax questions from Marshall Space Flight Center reps.]

Published August 2015

Rate this article

View our terms of use and privacy policy